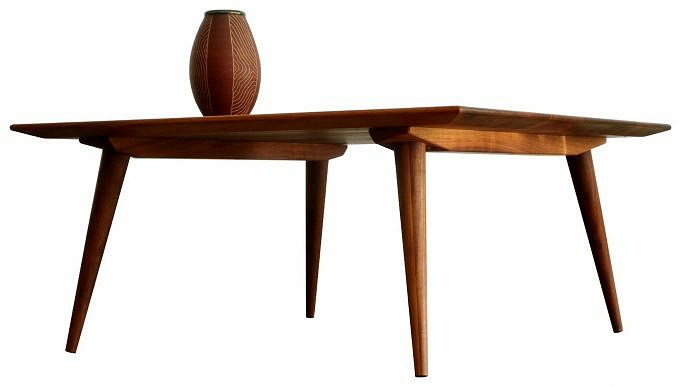

A table similar to this one was used by our family for board and card games. Unfortunately, I sold that table and have always regretted it. So when we finished out a couple new basement rooms for the kids, building a new game table was first on my list.

This table’s top is made of three boards of wormy-chesnut wood, which you will need to hunt down. It was purchased from a wholesaler in the Smokies. It was about a foot in length. Poplar is used to make the painted base.

Start the project by machining the legs and cutting taper.

There are a lot of ways you can join the aprons to the legs, from totally traditional to quick-and-dirty. Although I prefer a straight mortise and tenon joint, I would use the two other less common methods if I was building a small side table or anything else that wouldn’t see much daily abuse. Before we get to the bases, let’s build the top.

Making the top After I had pulled the correct boards from my woodpile I was ready to glue them up. The top should look rustic so I didn’t plane the lumber. Instead, I joined the edges of the planks together and glued the top. To get it flat, I used a belt sander and removed some milling marks. Next, I cut the top to the required size and finished the breadboard ends.

For many years, I used traditional through-mortises for attaching breadboards to my tabletops to cover the end grain. Other people showed my how to do it with slotted screw holes. I was always against using that method until I actually tried it. Now its the only way Ill attach breadboards. Screws are less effective at attaching breadboards and the top will stay flatter for longer. Heres how I make my breadboard ends.

Cut the breadboards to 3/20 cm in width by 2 after cutting them to size.

Cut two slots for each screw in each mortise. To give the top room to move, I made the slots approximately 3/20 cm in length. To cut the slots you can either use a router or a drill press to move the bit around. Clamp the breadboard to the table top and put two screws in each mortise. I put the screws at the sides of the mortise, not at the center. I do this because I peg the fake plug later in the process, and this keeps me from boring a hole into one of my screws accidentally. You don’t want the table top moving so you don’t need to drive them in too tight.

Now plug the mortises. I cut plugs to fit the opening and taper them a bit so they fit snugly when tapped in place. Then glue the plugs to the top and then use 1/10 cm x1/10 cm square pegs to fix the plugs.

Age the top. I use a keyring with many keys to strike the top. I also use a knife to write names on the top. Its pretty amusing to watch people as they see me do this. They get scared.

Apply a golden oak stain to the top, then apply a natural oil finish such as Watco. This is an oil/varnish combination. You dont want the top to look too shiny.

Plug the mortises. I made the plugs to fit into the opening. Then, tapered them a bit so that they fit snugly when they were tapped in. Glue the plugs in place, then peg the plugs through the top with 1/10 cm x 1/10 cm square pegs.

Now, turn your attention towards the base.

Mortise and Tenon

Your apron should be cut to the correct size. Cut apron lengths of 3 cm and tenons 3/20 cm in thickness. The apron lengths in the Schedule of Materials include the tenons. My tenons are cut first, and I use them to lay out the mortises. This results in a less complicated layout. These aprons are set back 1/10 cm from the front of the legs, this is called a set back.

Now cut a bead on the bottom edge of the aprons using a beading bit in your router. Finally, make a slot in the center of the apron for attaching the top to the base. Rockler makes metal tabletop fasteners. (See the list at the end). Rockler sells very sturdy ones, and I recommend them.

For these fasteners, the slot needs to be the width of your table saws blade (between 1/20 cm or 1/41 cm wide) and 7/41 cm down from the top of the apron and 3/20 cm deep.

Glue up your base, peg the mortises through the legs and finish the base. I use square pegs in my legs. Make a hole in the leg through the mortise. Then take a piece of square stock, whittle one end of it roundish, then pound it into the hole. This should make your hole square.

Mitered Mortise, and Tenon

This is similar to the straight mortise/tenon method, however you will need to miter the ends. Your mortises meet in middle of your leg. Why would they meet? You might have a shorter leg or your mortises may be farther back if you use a bigger set back.

When this is the case, I make a standard tenon and chop the end off at a 45-degree angle on my miter saw. You don’t have to match the miters exactly (it won’t show), so leave some space between the tenons. It could cause problems if it is too tight. The ends of the two tenons will touch the shoulders and seat into the legs.

Pocket Screws

This is not a good idea for large tables. If youre going to spend the money on the wood, you might as well do it right. This will work well if you are looking for a simple side table. Be sure to glue and screw this joint for added strength. Its important to keep the pieces tightly together as you screw the apron to the leg.

Corner Brackets

Corner brackets can be used as a fast alternative to traditional joinery but aren’t as strong. However, you cant beat them when you want to make a table that can be knocked down and stored away.

These measurements are applicable to brackets made by Rockler (see the box at the bottom of this article). The first step to installing these brackets is to cut a bevel on the inside corner of the legs. This is where youll later install the hanger bolts. The best way to cut the bevel is on your jointer. Set the machines fence to a 45-degree angle and the depth of cut to 1/10 cm. Cut 3-

Now install the hanger bolts, which are odd-looking fasteners that have wood screw threads on one end and machine screw threads on the other. The wood screw end goes into the leg, and the machine screw end is bolted to the corner bracket. First, drill pilot holes in the leg to install the hanger bolts. Then install the bolts using the method shown in the photo.

Now you need to cut a kerf in each apron for the bracket to grab. The kerf should be 1-3/10 cm in from the end and 3/20 cm deep for these brackets. Different brands may use different measurements.

Attaching the Top

I attach the top with tabletop fasteners that I screw in place about every foot. On the long aprons, dont push the fasteners all the way into the kerf when screwing them down. This will allow your top to move freely.

The base was finished with two coats of latex paint, followed by a glazing stain. For protection, I applied a few coats of lacquer. PW

Troy Sexton is contributing editor for .